This project looks at the development of a customized test adapter for Bizerba’s blanks. Bizerba is a renowned manufacturer of weighing, cutting and labeling technology, known for its high-quality products and innovative strength. The main task was to develop a test adapter that precisely meets the requirements of the Bizerba board. This board has special connectors on the sides, which makes it difficult to use conventional test adapters. This case study takes a closer look at the process of developing and implementing this customized test fixture to optimize quality assurance in Bizerba’s production.

Bizerba is a leading global manufacturer of weighing, cutting and labeling technology with an impressive history of over 150 years. The company is headquartered in Balingen, Germany, and has a presence in more than 120 countries. Bizerba is known for its high-quality and innovative solutions used in a variety of industries, including retail, food production, logistics and more

Challenges

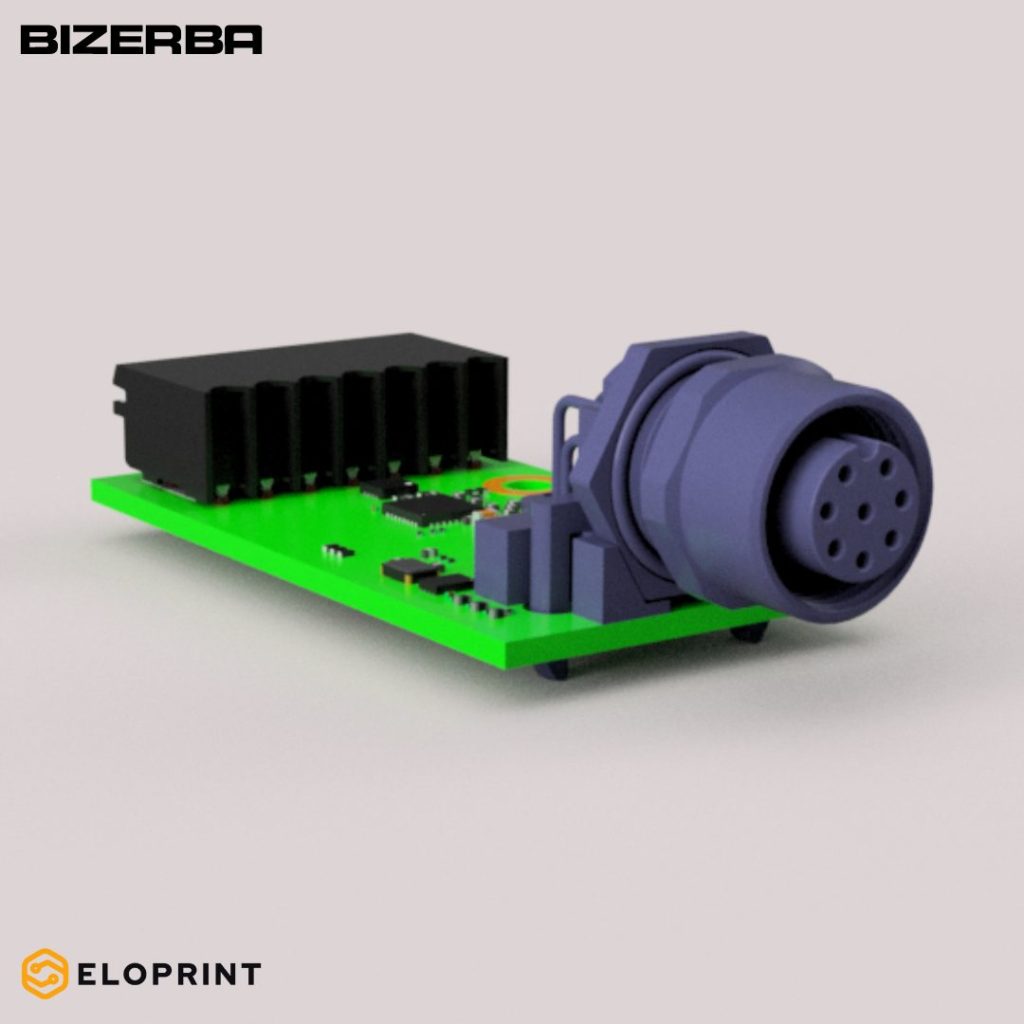

Developing a customized test fixture for Bizerba’s PCB was a particular challenge as the company needed a cost-effective and compact solution. The board is equipped with a SPT-THR 1.5 push-in spring connector on one side and a PCB connector, which makes it difficult to use conventional test adapters.

The main function of the board is to process serially transferable analog measurement data from weighing systems and convert it into a digital CAN protocol. This digital data is then forwarded to the new nTG terminal generations from Bizerba for calculation and display. The board thus functions as an analog/digital converter.

Bizerba was therefore looking for a partner who could offer a suitable solution. After a thorough analysis of various providers, the company finally opted for our company. Our expertise in the development of customized solutions and our flexibility make us the ideal partner for Bizerba.

In close cooperation, a test adapter was developed that met the technical requirements and was cost-efficient and compact. The solution was designed to not only meet current needs, but also to be durable in the long term and integrate seamlessly into Bizerba’s production processes.

Solutions

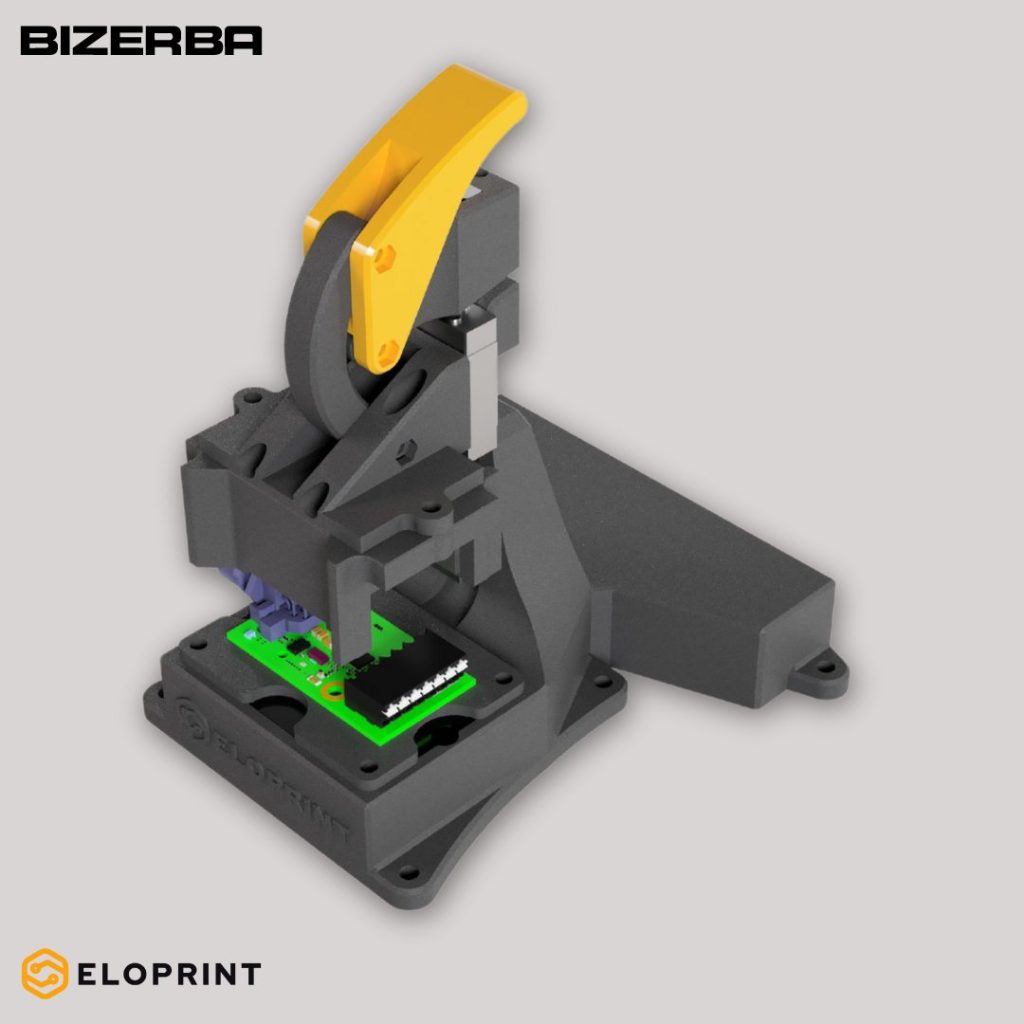

In order to test the Bizerba circuit board effectively, a customized 3D test adapter was designed. The 3D model of the board served as the basis for the concept, including the number of test points and their coordinates. This data made it possible to precisely position the test needles and test the individual components of the circuit board. The side cut-outs for the connectors were also taken into account by the 3D model of the circuit board.

Once the test adapter had been designed and printed using the FDM process, the individual test points were wired to the CNC-milled needle bed. To ensure that the test adapter functions properly, the circuit board is positioned over its edge or through holes using catch pins and placed on a spring-loaded carrier plate. When the test specimen is inserted, there is no contact with the test needles in the needle bed below. By actuating the lever, the individual hold-down device is moved from top to bottom and the PCB is pressed linearly onto the test needles. Assembled components are taken into account.

Advantages

The customized 3D test adapter offers several advantages for testing the Bizerba PCB:

Quickness

Thanks to our efficient design and manufacturing methods, we were able to deliver the test adapter from Bizerba within 6 weeks to meet the specific requirements. The entire process chain from design to 3D printing and assembly is covered in-house.

Flexibility in the application

Individual requirements are no problem for us. We can customize the test adapter exactly to our customers‘ needs, including different connectors, limit switches or display elements.

3D Print

Thanks to 3D printing, we can produce the test adapter quickly and cost-effectively without compromising on quality. The shape and size of the adapter is customized to each test specimen so that the space required and the

costs are never higher than necessary.

Ready for precise and reliable testing? Contact us today to learn more about how our test fixtures can improve your applications. Your technical challenges are our mission!